Introduction

T-shirt printing has transformed from a simple craft into a multi-billion-dollar industry.

Whether you’re an entrepreneur looking to start a business or a hobbyist who wants to create custom designs, choosing the right t-shirt printing machine is the first crucial step.

But with so many different types of machines on the market, making the right choice can feel overwhelming.

Understanding the different printing methods, their costs, and their ideal use cases will help you make an informed decision.

This guide breaks down everything you need to know before buying a t-shirt printing machine—from the different types available to key considerations that will impact your purchase.

Types of T-Shirt Printing Machines

Not all t-shirt printers work the same way. Some are better for small businesses, while others are suited for high-volume production. Here’s a breakdown of the most common types.

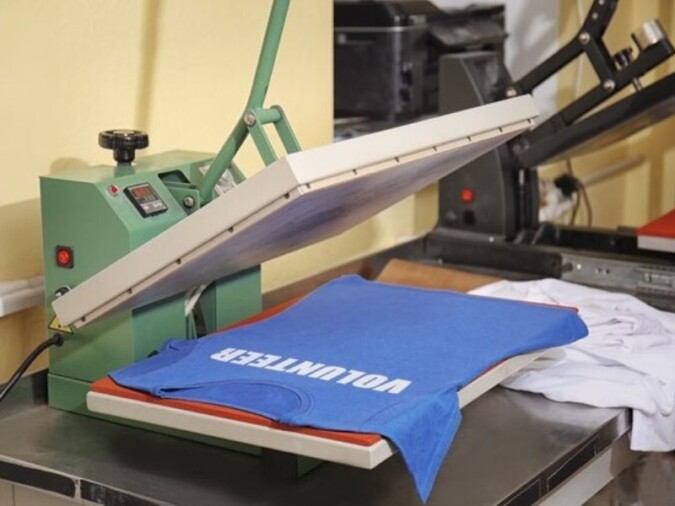

Heat Press Machines

A heat press machine is one of the most accessible options for t-shirt printing. It works by transferring a design onto fabric using heat and pressure. The design can be made using vinyl cutouts, sublimation transfers, or inkjet transfer paper.

Heat press machines are popular among beginners because they are easy to use and relatively inexpensive. However, they are limited in terms of color complexity and are not the best choice for high-volume printing.

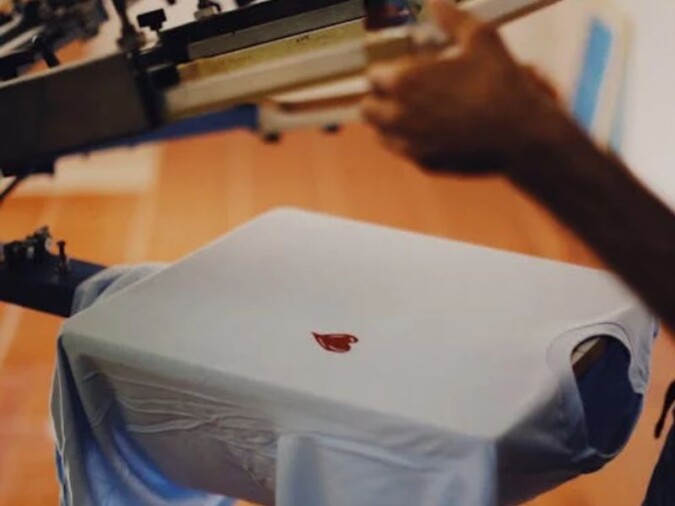

Screen Printing Machines

Screen printing is one of the oldest and most durable methods of printing on fabric. It involves creating a stencil, or screen, for each color in the design and pressing ink through the screen onto the fabric.

This method is widely used in commercial t-shirt printing because it produces vibrant, long-lasting prints. However, screen printing requires more setup time and is not ideal for one-off designs or small-batch production.

Direct-to-Garment (DTG) Printers

A DTG printer works like a regular inkjet printer but prints directly onto fabric instead of paper. This method allows for highly detailed, full-color prints and is perfect for custom designs or small batches.

DTG printing doesn’t require screens or transfer paper, making it a more straightforward process than screen printing. However, the machines can be expensive, and the ink costs can add up over time.

Sublimation Printers

Sublimation printing is a heat-based technique that turns ink into gas, bonding it permanently to polyester fabrics. This process creates vibrant, fade-resistant designs that last as long as the fabric itself.

One downside of sublimation printing is that it only works on light-colored, synthetic materials. If you primarily want to print on cotton shirts, this may not be the best option for you.

Vinyl Cutters & Transfer Printers

For simple graphics, lettering, and logos, vinyl cutting machines are a great option. They cut designs from sheets of colored vinyl, which are then heat-pressed onto fabric.

Vinyl printing is often used for sports jerseys, promotional shirts, and custom name designs. However, it is not suitable for complex, multi-color images since each color needs to be cut and applied separately.

What to Consider Before Buying a T-Shirt Printing Machine

Before investing in a t-shirt printer, it’s essential to think about your needs, budget, and long-term goals.

Budget and Costs

T-shirt printing machines vary widely in price. A basic heat press can cost less than $200, while high-end DTG printers can run into the thousands. In addition to the machine itself, consider costs for ink, transfer paper, maintenance, and any software needed to create designs.

Print Quality and Durability

Some machines produce more vibrant and long-lasting prints than others. Screen printing and sublimation tend to be more durable, while heat press designs can crack or fade over time. If you’re selling shirts professionally, investing in a high-quality machine will save you money in the long run.

Production Volume

If you only plan to print a few shirts at a time, a heat press or DTG printer is a great choice. For larger-scale production, screen printing is more efficient because it allows for batch printing with lower ink costs per shirt.

Ease of Use and Learning Curve

Some machines are plug-and-play, while others require extensive setup and learning. A heat press is beginner-friendly, whereas screen printing and DTG require more skill and practice. Consider how much time you’re willing to invest in mastering the technique.

Maintenance Requirements

All printing machines require some level of maintenance. DTG printers, for example, need regular cleaning to prevent ink clogging. Screen printing requires washing and reclaiming screens after each use. The more complex the machine, the higher the maintenance.

Best T-Shirt Printing Machines for Different Needs

If you’re just getting started, a heat press machine is the easiest way to begin. It’s affordable, simple to use, and doesn’t require special training.

For small business owners, a DTG printer offers the flexibility to print intricate designs on demand. It’s a great option for customized, one-off prints or short-run orders.

Those printing in bulk will benefit from a screen printing setup. While it requires more time to prepare, the cost per print is significantly lower when producing large quantities.

For the best color vibrancy and print durability, the Prestige R2 Pro DTF printer is an excellent choice. It allows for high-resolution designs that last through multiple washes.

Mistakes to Avoid When Choosing a T-Shirt Printer

One of the most common mistakes is ignoring the long-term costs of maintenance and supplies. A cheap machine may seem like a great deal, but if the ink and materials are expensive, it could cost you more in the long run.

Another mistake is choosing the wrong printing method for your needs. If you want to print highly detailed, multi-color designs, a vinyl cutter won’t be the best option. Similarly, if you plan to print on cotton, a sublimation printer won’t work.

Failing to research compatibility is another common pitfall. Not all printers work with all fabrics. Some require specific inks or transfer materials, so it’s important to check the specifications before making a purchase.

Getting Started with Your New T-Shirt Printing Machine

Once you’ve chosen the right printer, the next step is setting it up. Most machines come with basic instructions, but it’s a good idea to watch tutorial videos or join online communities for additional guidance.

Before printing your first batch, test a few sample shirts. This allows you to fine-tune settings like temperature, pressure, and ink saturation. Making adjustments early on will help ensure better results in the long run.

As you get more comfortable with your machine, experiment with different fabrics, inks, and techniques. The more you practice, the better your prints will become.

Conclusion

Choosing the right t-shirt printing machine depends on your goals, budget, and experience level. A heat press is great for beginners, while screen printing is ideal for mass production. DTG and sublimation printers provide high-quality prints but come with higher costs and maintenance requirements.

Before making a purchase, take time to compare options, read user reviews, and factor in ongoing costs. Investing in the right machine from the start will set you up for success, whether you’re printing for fun, business, or both.

With the right tools and a little creativity, you can turn your t-shirt printing ideas into reality. Happy printing!