Air pollution doesn’t just rise from traffic or wildfires. Many of the worst airborne pollutants drift out of industrial zones daily—microscopic particles, chemical gases, and toxic compounds. These emissions don’t just poison the air. They create a cascade of health issues and environmental hazards that hit nearby communities the hardest.

The solution starts with how industrial waste is handled. Not dumped. Not ignored. Managed.

Airborne industrial waste can be reduced sharply with better planning, better equipment, and accountability at every step. That’s what this article is about. Not theory—practice. Below you’ll find tested strategies, useful tools, and real-world principles to reduce air pollution through responsible waste management.

Key Highlights

- Airborne waste from industry poses direct threats to human health and air quality.

- Proper segregation and cleaner technologies reduce toxic emissions at the source.

- Recycling and material recovery lower the need for fresh resource extraction.

- Community-focused regulations can push companies toward cleaner practices.

- Consistent waste audits lead to long-term compliance and air safety.

The Real Impact of Airborne Industrial Waste

Factories release more than smoke. Exhaust stacks often carry fine particles, VOCs (volatile organic compounds), and metal-rich fumes into the air.

Health and Environmental Fallout

Long-term exposure increases risk of:

- Asthma

- Lung cancer

- Neurological disorders

Heavy metals like mercury and lead settle in soil and enter local food chains. Nearby vegetation suffers stunted growth and lower yields.

The link is proven. According to WHO data, air pollution contributes to 7 million deaths annually worldwide. A large portion of that comes from industrial activities.

Waste Practices That Cut Emissions

Cutting emissions starts with smarter waste practices. By changing how industries handle airborne pollutants, it’s possible to reduce harmful output without halting production.

1. Reduce Waste at the Source

Fewer emissions start with less waste to begin with. Every step of production that avoids unnecessary material use prevents pollutants before they form. This means redesigning processes to use fewer raw inputs, switching to cleaner materials, and avoiding overproduction. It’s the most direct way to control pollution ─ by never creating it in the first place.

How it’s done:

- Redesign production to use fewer inputs.

- Replace toxic materials with eco-safe alternatives.

- Automate batching to avoid spills or overflows.

Table: Common Substitutions to Reduce Waste

|

Harmful Material |

Sustainable Replacement |

| Chlorinated solvents | Water-based cleaners |

| Coal-based fuels | Biomass or clean gas |

| PVC packaging | Biodegradable polymers |

Fewer materials in = fewer emissions out.

2. Adopt Cleaner Technologies

Modern tools can make the biggest difference.

Industrial baghouse dust collectors are a prime example. These systems use fabric filters to trap particles from exhaust air before it leaves the facility. Torch-Air designs custom units for different dust types, providing long-term filtration at scale.

Other critical tech:

- Scrubbers for chemical gas removal

- Cyclone separators for coarse particle collection

- Enclosed conveyors to minimize dust release

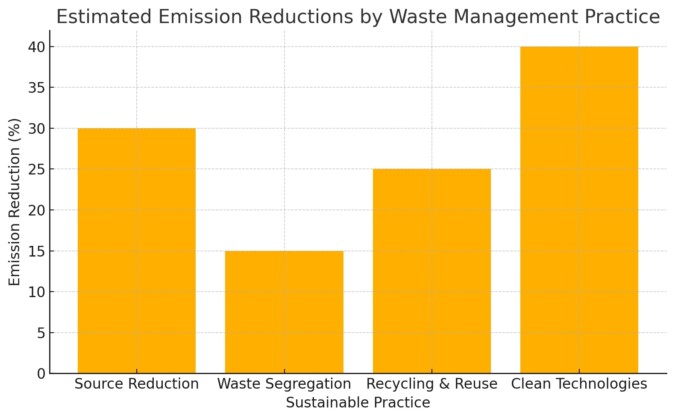

Chart: Emission Reduction by Waste Practice

This chart compares four widely adopted waste management strategies and their estimated effectiveness in reducing industrial air pollution. Clean technologies, such as dust collectors and gas scrubbers, rank the highest with potential reductions reaching up to 40%. Source reduction follows closely at 30%, while recycling and reuse contribute 25% on average. Efficient waste segregation plays a smaller but essential role, accounting for 15% in emissions savings.

What this means is clear: investing in cleaner tech gives the fastest and most measurable results ─ but it works best when paired with reduction and recycling strategies.

3. Segregate and Treat Waste Efficiently

You can’t manage what you don’t separate. Sorting waste by type makes treatment more effective and targeted. It prevents cross-contamination, cuts down on secondary emissions, and allows for safer, cleaner processing. Segregation also enables recovery of valuable materials, reducing reliance on new resource extraction.

Key actions:

- Sort waste into hazardous, non-hazardous, and recyclables.

- Install labeled bins and sealed containers inside facilities.

- Use color-coded collection to prevent cross-contamination.

Why it works:

- Prevents chemical reactions that can trigger airborne releases.

- Keeps recyclables cleaner for reprocessing.

- Reduces volume going to incinerators, cutting airborne byproducts.

4. Reuse and Recycle Smarter

Closed-loop systems help recover materials that would otherwise pollute. Instead of dumping waste, industries can reintroduce usable components back into production. This reduces the demand for raw materials and lowers the energy needed to process new inputs. Smarter recycling also means tracking material flow and investing in technology that separates and purifies waste more efficiently.

Benefits:

- Cuts raw material demand.

- Saves energy on processing.

- Reduces pressure on landfill sites.

Example:

- Used oil filters can be cleaned and recirculated.

- Metal scraps were melted and molded for new tools.

Recycling is not just about plastics. It’s industrial, and it works.

Legal Responsibility and Community Involvement

No factory operates in a vacuum. Industrial emissions hit the people living next door first. That’s why local laws and public pressure matter.

Regulation plays a critical role in enforcing cleaner industrial practices and reducing airborne waste. Authorities set clear air quality thresholds that facilities must not exceed. These limits define how much particulate matter or harmful gas can be released into the environment during operations. When companies violate these limits, penalties apply. Fines, legal action, or even temporary shutdowns serve as strong incentives for compliance.

In addition, regulations require regular environmental audits and formal permits for any company that handles or disposes of industrial waste. These legal checks ensure that only qualified operators manage potentially hazardous materials and that proper safety measures are consistently in place.

Community engagement builds trust:

- Offer air quality reports to local councils.

- Hold open-door days for transparency.

- Fund local green initiatives tied to the site.

The more residents understand how waste is managed, the more likely they’ll support the business.

When It Works ─ Industry Success in Action

Take a look at these outcomes from companies that implemented sustainable waste reforms:

|

Company |

Change Made |

Result |

| Metalworks Inc. | Installed baghouse filters | 91% drop in airborne metals |

| EcoPoly | Switched to reusable molds | Cut plastic scrap by 70% |

| TechFume | Built in-house recycling loop | Saved $400K/year in waste fees |

These aren’t startups. These are large-scale operations making changes that deliver.

Final Thoughts ─ Cleaner Air Starts at the Factory Floor

Cleaner air isn’t just a policy goal. It’s a product of better decisions made every day in industrial settings. Every filter installed, every toxic material phased out, every bin properly labeled—that’s what real air quality improvement looks like.

Managing airborne industrial waste means accepting responsibility for every molecule that leaves the building. With the right tools and commitment, that responsibility turns into cleaner skies and healthier communities.